Skåne, Sweden

Andreas Lebisch, architect and sustainable construction business developer, gives us insight into the incredible potential of timber for sustainable construction and how his country home, Villa Skäret or Kvartshus, featured on Grand Designs Sverige, grew out of his sustainable ideals.

Andreas’ career has been defined by a passion for design and a drive toward sustainability. He thinks it is important to challenge construction conventions, especially when considering shared social and environmental challenges. We spoke with him about how his career impacted his family's summer home's design and build.

Andreas points out that there is a lot of waste in a typical construction process, starting with the material, but challenging conventions in construction can be daunting. The processes and materials chosen for construction projects are long-entrenched and are a big part of why the construction industry is responsible for 39% of all carbon emissions.

"Being responsible for the finances of a project means using resources wisely. Every single building part must be counted, and it is important to find sustainable solutions that last a long time with as few emissions as possible."

— Andreas Lebisch

In his role as a sustainable business developer, Andreas is an advocate for a scaled approach to sustainability that makes business sense for his firm’s clients. Aiming for better, not perfect, can help sustainable practices move into the mainstream more quickly.

“On some projects, I have one leg in the old days and the other in the future — new techniques and old techniques can come together to make significant changes to the future of our planet.”

— Andreas Lebisch

Andreas and his firm run a climate analysis of all their buildings before they build and afterward. The Swedish government incentivizes high-performance buildings, which makes it easier to bring clients on board to new ways of sustainable construction.

Using timber for a sustainable future

Timber is an excellent construction material in terms of carbon emissions, especially when considering timber versus steel or concrete. When aiming for sustainability, the whole lifecycle of a building’s materials needs to be considered; it’s crucial to prioritize materials that lead to high performance after the ribbon-cutting and are also sustainable to create.

Timber is a renewable resource that grows naturally, especially in environments like Sweden’s forests. Steel and concrete are carbon-heavy to create, and after the building process, they don’t do anything to offset carbon in their environment. On the other hand, timber is carbon-negative because it collects and stores carbon from its surroundings.

CLT (cross-laminated timber) is a material that allows for a lot of flexibility. It can be cut in prefabricated shapes in a shop, and then quickly assembled on-site. Leveraging prefabrication in construction can dramatically cut down on construction waste and surprises in time or budget.

Wood also makes for spaces that are pleasant to be in. Because it is porous, wood changes with the humidity of its surroundings and traps excess carbon in the air, making it a natural air purifier. Timber has a lot of insulating quality; it also keeps warm air inside in the winter.

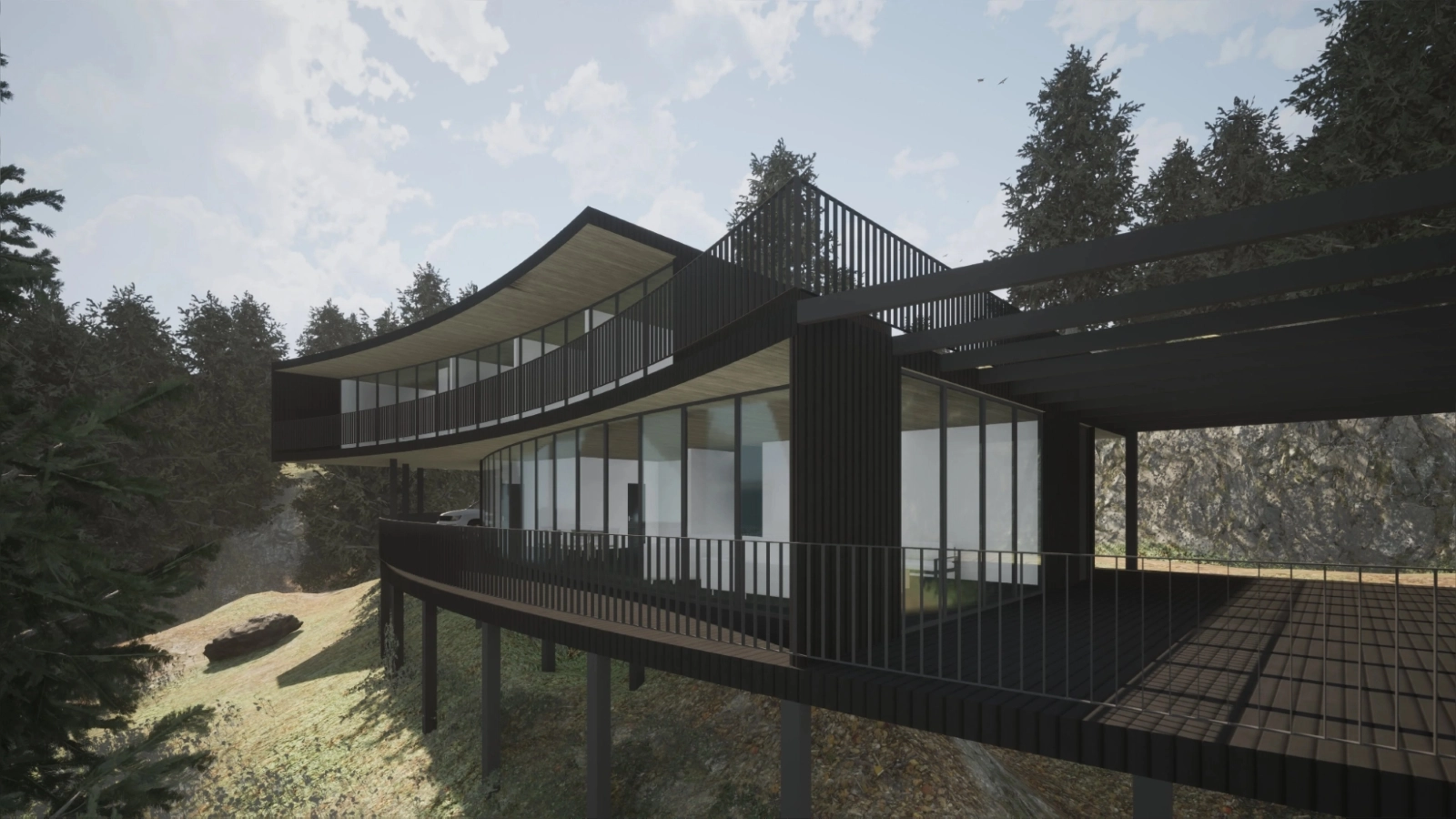

Sustainability meets natural beauty: Kvartshus from Grand Designs Sverige

With his design, sustainability, and business background in mind, Andreas approached the design and build of his family’s holiday home, Kvartshuset. The home was featured on an episode of Grand Designs Sverige, an architecture and design TV show that followed his family’s design journey for two years.

Shaping the design of Kvarthus

As with any architectural project, Andreas began Kvartshuset’s creation by studying the surrounding context. His family built a wooden platform and camped on the empty plot of land for two summers to get a feel for the place, how it changed day-to-day, the movement of the environment outside of their plot, and the way the naturally growing plants ebbed and flowed. Through their immersive observation, they found the perfect site for their home — at the lot’s highest point, tucked away amongst trees and stone formations.

Andreas was inspired by the local landscape and the dramatic cliffs surrounding the nearby shore. He wanted to create a house that resembled a natural formation, rising out of the ground like the boulders and trees that stud the lot. He honed in on the idea of using a crystal as his shape inspiration, sketching the outline of his house in the kinds of random yet geometric shapes they grow in.

“As humans, we like symmetry, we like organization, and then we usually stop there in a design. The location of a place or its surroundings should play more in the structure of the building, and that's why we take inspiration from natural formations. A tree will not have exactly similar branches on both sides. It will probably grow slightly different according to wind and weather. The form of the house feels natural because it follows its surroundings.”

— Andreas Lebisch

To maintain a sense of calm and symmetry in a more maximally-shaped design, he decided to work with a minimal material palette: wood and glass. The house is all Swedish spruce, inside and out. Spruce grows very well in many parts of Sweden and is a major export product for construction uses and as a paper material.

He tried to limit the amount of smaller holes inside the volume of the house — it's either very closed planes or very open to keep the exterior shape as pure as possible. Another design goal in service to the calm, minimalist aesthetic was to hide functional details as much as possible. The fewer visible details, the more difficult it can be to build. For example, all of the water-bearing elements on the roof — the gutter, the rain pipes, and the connecting systems — are hidden inside the structure to keep the house uncluttered and as straightforward as possible.

Andreas’ wife, Anna, is a landscape architect. Though they want to do minimal alteration of the natural space the house sits in, she helped Andreas with how the house would flow into the exterior and the gentle shapes they could form outside to promote harmony between the terraces that extend out of the house and the landscape there. Andreas and Anna used SketchUp to visualize their ideas to each other.

Photographs of Kvarthus and its interior to exterior connection.

The CLT and timber design-to-build workflow

Andreas worked with 2D plans and his 3D SketchUp model in parallel to ensure he would have the right information when it was time for fabrication.

“You can have the efficiency of the plan layout, but then know the effect on the 3D and then back again. So it's a bit of a symbiosis between plan and model.”

— Andreas Lebisch

Andreas used SketchUp to model construction details.

After Andreas modeled his final design, he sent it to a structural engineer for analysis and 2D documentation. Through an early interaction with the structural engineer, Andreas and the engineer realized the whole shell could be built out of thick CLT so the structure would bear itself up without beams or columns. The shell material is CLT, that's 25 centimeters thick and acts as insulation, so Andreas did not have to add much between the shell and the cladding.

“Because the wood insulates enough, it's solid, almost like a log cabin — old school meets CLT technology.”

—Andreas Lebisch

In the early stages of his design process, Andreas knew that he wanted to use CLT and timber as his construction material because timber is more sustainable and easy to shape and manipulate, giving him freedom in his organic-inspired design. For a simple structure with a deceptively complex shape, he liked that CLT can be prefabricated to precisely the right angle and to the millimeter.

SketchUp model showing exterior framing details.

“Using SketchUp, you can create three-dimensional shapes that are useful as a guide to precision cut out the elements you want from the model. It’s a straightforward process, which is incredibly helpful.”

— Andreas Lebisch

Using a 3D model was a critical part of Andreas’ fabrication workflow. Because the shape of the design had so many sides and angles, creating flat section cuts of the whole building would take an enormous amount of time. There were so many pieces with such small differences in degrees it would have been nearly impossible to maintain the precision needed to build a whole house.

Andreas found that the simplest way to communicate with his fabrication team was to send them 3D files they could feed into their CNC machine. The fabricators sent 2D drawings back to Andreas to ensure they were getting everything right. He checked the shop’s 2D drawings against the measurements he had in his model. Once everything was confirmed, they used the CNC machine to cut each piece of CLT, sand it and prepare it for the build.

Photographs showing the construction of Kvarthus in progress. Click through to see the home coming together.

The fabrication team cut about 110 unique elements for the CLT shell of the structure, which they then wrapped and delivered to the building site. Andreas worked out the sequence with the structural engineer, using his 3D model to visualize how the construction would go. Once the construction team started, it took them about five days to assemble the structure, working in sequence on a giant, house-shaped wooden jigsaw puzzle.

After the shell was completed, the house was almost done. They chose an all-timber interior to keep the design aesthetically minimal and to build on the sustainable theme of the home. Andreas had worked with another fabricator for thinner CLT for the interior, which was fabricated in the same way as the external shell. The construction team lightly sanded the interior wood and gave it a thin coat of white-pigmented treatment to prevent it from yellowing as the sun breaks down the fibers.

The interiors are all timber, as well. Click through to see different views of the completed interior.

Andreas and his family decided to leave the external timber cladding untreated to keep it natural. Their family has been admiring the color of the untreated wood and how it naturally shifts alongside the landscape it sits within.

“In the beginning, it was white wood; it had this incredibly light color, like freshly cut bread. Over time, it's becoming increasingly gray on the outside as it changes with the weather. When it’s wet, it’s almost black.”

— Andreas Lebisch

After a couple of years, the color of their family’s modern wood cabin may change, but the construction has proven stable and comfortable.

The completed home perched on the highest point of the family plot.

Andreas, Anna, and their family have been able to enjoy their timber home in all seasons thanks to the wonderful structural and insulating qualities of the CLT shell. Even better, they have a sustainable home that will stand the test of time.

If you want to create a fantastic timber structure using the latest technologies, you can try SketchUp for free.